Hot glue is currently the most environmentally friendly type of adhesive that is suitable for high-speed automatic production lines. With the rapid development of the automotive industry and the improvement of the automation level of automobile production, the automotive industry needs a large amount of fast and environmentally friendly adhesives that can adapt to high-speed automated production. Hot glue can meet all the above requirements, and therefore its application in the automotive industry is becoming more and more widespread, with the usage increasing year by year. Hot glue can be used in the car gluing application and has become an irreplaceable type of adhesive in the automotive industry.

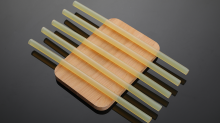

Most hot melt adhesives have examples of use in cars, but different types of hot melt adhesives are selected for different parts and purposes. According to their functions, main types of adhesive used in the automotive industry can be divided into two categories: bonding type and sealing type. Sealing type mainly uses Butyl-based glues and will not be discussed here. If classified according to usage and construction temperature, they can be divided into ordinary type and heat-resistant type. Since automobiles usually travel outdoors, hot glue is required to have a certain degree of heat resistance. According to the material classification, there are EVA, rubber, APAO, PUR, PA, PES, etc. The shapes include block, film, rod, particle, and powder.

A car is composed of thousands of parts, and there are many parts that involve the use of hot glue. The commonly used ones with large usage are as follows:

Headlights

The traditional method is to use rubber sealing strips with holes and seal them by tightening screws. After using automotive mirror glue, it can be quickly bonded and perform the sealing function at the same time, which not only reduces costs but also benefits automated production. The types of hot glue used are mainly rubber type, APAO type, PUR type, etc. It is required to have good temperature resistance, high bonding glass strength, and vibration resistance. There are also dual-component adhesives used. Temperature-resistant hot melt adhesive rods are also used to fix wire harnesses and electronic components for license plate lights.

Dashboard, ventilation ducts, and interior fixing buttons

Fixing connections via mechanical methods is not only time-consuming, but also inefficient, and the sealing performance is not good. After adopting hot glue, the production efficiency and product quality are greatly improved. Heat-resistant hot glue sticks are mainly used, and the base materials include EVA and polyolefin types.

Car roof

The car roof is a composite of plastic sheets, and the types of hot glue mainly include film and powder adhesives, with PE and EVA as base materials.

Car door panels

Hot glue is used for bonding in assembling car door panels, including PP bonding, fixing of sound systems and wire harnesses. APAO and heat-resistant hot glue sticks are mainly used.

Car carpets, floor insulation mats, and luggage compartment locking buttons

This is where hot glue is used the most in cars such as automotive carpet glue and other types of automotive adhesives. The types of hot glue include blocks, granules, and bars. The varieties include pressure-sensitive adhesive, EVA granules, APAO bars, etc. It requires long open time, easy to assemble and fit large parts, good heat resistance, and less odor.

Fixing wire harnesses in the car

There are a large number of wires inside the cars, and it is not possible to fix so many wire harnesses like in household decoration. Using hot glue to fix the wire harnesses is a time-saving and efficient method, and hot glue has a certain degree of elasticity, so it will not fall off during the trip. It is easy to disassemble when maintenance is needed. The main types of hot glue used are sticks and APAO.

We assured you that your personal information will be kept confidential. The personal data we collect is only used to process your inquiry.